ClayHound Web

- Catawba Pottery

ClayHound Web

- Catawba PotteryReturn to:

|

The Catawba are located in north-western South Carolina. The pottery is characterized by the dark clay of the east, but can end up with several different colors depending on the type of wood used during the firing process. |

|

|

|

|

|

|

|

|

Historians Claim that Native American pottery making techniques in the United States was first discovered in Coastal Carolina over 4,500 years ago. Archaeologists divide this long period of pottery making into two broad periods: the Woodland and the Mississippian. Modern Catawba pottery, a skill passed down within the tribe, reflects the techniques of both of these periods. |

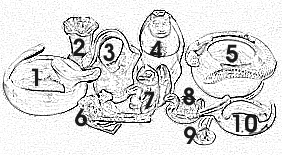

MISSISSIPPIAN CONSTRUCTION METHOD ENDURES, for the Catawba attach all legs, handles and lugs through the walls of the vessel. For instance, to turn a cooking pot into a gypsy pot, the potter measures off places for three legs, bores holes at these locations, and inserts pre-constructed legs into the holes. These are then clamped on the inside and smoothed into the vessel’s walls. The same process is followed in attaching the two handles required to make a gypsy pot.THE UNIQUE CATAWBA FINISH is applied with a rubbing rock. A quality Catawba vessel is burnished with a stone until it has a velvet finish. So high is this polish that some buyers of Catawba pottery mistake this finish for glaze, but the Indians never use glazes or paints on their wares. Sometimes while the vessel is still wet, but after it has been polished, the potters will incise a vessel with fine line drawings. These are traditional in nature and form yet another Catawba link with pre-Columbian times. The corpus of motifs is small: straight lines, cross hatch, ladder, feather, curved lines, zigzag, and the cross or swastika.BURNING THE VESSEL IS THE LAST STEP IN THE PROCESS The Catawba have always shunned the kiln. Catawba pottery is burned in a bonfire. To begin, the pottery must be completely dry. The potters must also wait for a sunny day without wind. When the best day dawns, the wares are placed in the kitchen oven or in a ring around the fire where they are exposed to a low heat. As the drying process nears completion, the intensity of the bonfire or the temperature in the oven is increased until the vessels are dry enough and hot enough to endure the full fire without breaking. When the potters decide it is safe to do so, the vessels are exposed to the full heat of the bonfire. Wood is placed on top of them and allowed to burst into flames. Burning a load of pottery is an all-day affair.THIS PART OF THE CATAWBA PROCESS IS HAZARDOUS because here is where the potters may lose hours of labor. A small undetected stone or air bubble in the walls of a vessel will cause a crack. If the vessel is too thick it may not take the stress of fire well and crack. If an appendage is improperly attached, it may pop off in the fire.BUYING CATAWBA POTTERY IS AN ADVENTURE The Catawba have always been determined to protect the purity of their tradition. As a result, collectors from around the world visit the Indians to buy pottery. Museums are also eager to add Catawba vessels to their collections. A vessel which is properly fired and has no cracks will have a ring when flicked with the finger. The burnishing should be evenly applied so that one can hardly see the marks of the rubbing rock. The incising should be well drawn, smooth and even.ANIMAL EFFIGIES AND SMOKING PIPES ARE USUALLY MODELED BY HAND but in the 19th century, the Catawba observed settlers making pipes with squeeze molds. The inventive Catawba copied these molds in clay so they might compete with commercial potteries. Today, most Catawba who build pipes use such squeeze molds. Some have been passed down within families for as long as five documented generations. The delicate task of making pipe molds has enjoyed a recent revival among the potters.The Secret to Catawba Survival is its pottery. Today the Catawba are the only Indians east of the Great Pueblos of New Mexico to retain this aboriginal craft in a nearly pure state.When We Buy Catawba Pottery… We Invest in HistoryTHE CATAWBA PROCESS begins at the clay holes. These secret, carefully guarded, river-bottom locations are visited by family groups as clay is needed. As a rule, the men dig until clay of a good quality is reached. The Indians call this pipe clay. Used alone, it can be used to make small pieces such as the famed Catawba smoking pipes. To make larger pieces, the potters add pan clay. This clay is gritty, and it adds strength to the walls of the vessels.The Catawba Indians protect the ancient way of mixing clay in order to form the vessels.THE CATAWBA DO NOT USE THE POTTERS’ WHEEL All their vessels are built by the coil or morsel methods. The tools consist of skilled hands, sticks, shells, knives, spoons, and rocks. For a large vessel, the potter makes a flat base and then adds rolls (coils) until the desired height is reached. The exterior is then smoothed with a shell or a corncob. As the interior is worked, the potter gives the vessel its graceful shape.Good information from a website of Caroleen Sanders, a Catawba potter - http://www.hafwacked.com/catawba.htm |

|